How to Apply Gelcoat to Your Boat

To maintain the look and sea-worthiness of your ship, Gelcoat is necessary. Gelcoat is not only a nice resin that makes the vessel look nice; it protects the surface of the fiberglass and serves as a barrier to the absorption of water.

It’s like painting on window frames: the paint colors with time, and it begins to flake and disappear. The rain gradually soaks into the wood and starts rotting the frames. Your ship is the same! Imagine the punishment it takes, day after day, under the waterline.

Simply put, the gel-coat will keep you afloat.

Can I Apply Fresh Gelcoat Over Existing Paint?

My short answer to this question is yes. But first, make sure it is free of dirt and debris on the surface. Using the window frame example again, without preparing the wall, you will not be adding fresh paint over old paint. Within months, the paint would chip away and you would have rotting frames.

If it’s blistered, it is advisable to remove as much of the old gel coat as possible. Starting with 40 or 80 grit and finishing with 100 or 200 grit, use low-grade sandpaper and scale it up. That should remove debris and rough up the surface sufficiently to bind with a fresh gelcoat. The trick will be accomplished by a power sander, bringing the blistered region back to the fiberglass.

Apply the new coat directly on top of the old gelcoat that has become faded but still fine. As a perfect substrate, the old Gelcoat will work and allow the new coat to harden.

Proper Preparation is the Key

There are fundamental housekeeping principles to address before I get into how and when to spray gelcoat:

- Stop applying gelcoat in clear light from the sun.

- Carefully pick your day and watch the weather. At temperatures below 60 degrees F and above 80 degrees F, never apply gelcoat.

- Allow ventilation to occur. In an enclosed space, never apply gelcoat.

- Remove all attachments: cleats, seals, and cords. Apply duct tape instead of masking tape, if necessary (it bonds better and gives a better seal).

- Duct tape around portholes, and everything in contact with the gelcoat you do not like.

We should get on with the preparation of the surface to be gel coated now.

Clean and Sand the Exterior of Boat

Ever heard “The Devil is in the detail?”

In a smooth, well-bonded, and professional-looking Gelcoat, the boring prep work is where you excel or fail. So take your time and make it perfect. Sanding the surface will make any lumps or bumps smooth out.

Don’t believe they’re not going to show through either. After you’ve done the Gelcoat, all you’ll see are places where corners are cut and a “that’ll do” mentality is embraced.

Run your hand over to feel its smoothness after the surface is sanded. Bumps still? Continue sanding!

Repair All Hull Damage

You can need to fill up before you sand, depending on the size of the dent. For this work, here are some great products on the market:

Glass Reinforced Filler Bondo (Check Amazon): This filler sets easily, allowing two minutes of sanding. It works on wood, fiberglass, and other materials as well.

Marine-Tex White (): Perfect for repairs, dent (Check Amazon) filling, and scratching. This filler is also versatile; it binds with wood, metal, fiberglass, and even masonry.

When you have all the dents found and filled, grading the sandpaper is important. Start with 40 to 80-grit as before and then scale up to 100-grit sandpaper. This ensures smoother feathering, which makes it easier to add the first coat of the resin.

Until set, to smooth it like a professional, rub the filler down with a high-grade 180 or 200-grit sandpaper.

Wipe the entire surface with Acetone after you’re pleased with the finish, to remove any grease or dirt. It makes the Gelcoat bind with the surface better.

Work Outside or in a Well Ventilated Area

I listed applying gelcoat using well-ventilated areas, but on the flip side, you should also avoid the outdoors. You don’t want dust to get on the fresh new layer of your gel coat. Speak to marinas; inquire for appropriate facilities such as drydocks and poly-tunnels.

Make sure you still wear enough protection for the face and hand!

Mixing the Gelcoat

Calculate how much you will need before adding the Gelcoat.

A 14-foot hull can cover one quart of gel coat, at a thickness of 10 to 15 mils. You can need to re-coat areas, but it should be no greater than 20 mils in depth.

The Gelcoat should be prepared in 5 oz batches, as a rule of thumb. Here’s why: While it is possible to blend more substantial amounts, the pot life is dramatically reduced. You’ll have 15 to 20 minutes or so to add the first coat.

Even, you may want to apply a sanding aid like FGCI Wax Additive before you add the thinner (Check Amazon). Once the gel coat is applied, this facilitates the sanding process. It helps cure the resin at room temperature and makes it easier to sand a less tacky surface.

Thin the Gelcoat with Paint Thinner

When using a gravity-fed spray gun, just add thinner (Check Amazon). The Gelcoat can be added thicker to the professional standard “Cup” pistol. Though a less smooth finish is the downside.

Gelcoat is widely used in two types of thinners: reactive thinners and evaporative thinners.

Both do the same job, except that reactive thinners combine to become part of the gel coat, while evaporative thinners dissipate to leave mostly pure Gelcoat within the resin.

Mix in Chemical Hardener

The gelcoat package supports the hardener, or Methyl Ethyl Ketone Peroxide (MEKP). Here’s a rough guide to the quantity required to apply to the mixture of gelcoat:

You will need 0.625cc of MEKP per ounce of gelcoat if you’ve used a thinning agent like Patch-aid (Check Amazon),

This equates to 12 to 18 drops per ounce of MEKP.

You’ll need to add 11cc (about 165 drops) per quart of gel coat to scale up. If a large one-gallon batch of gelcoat is combined, then you will need to add 40cc or 600 drops.

Remember: you will only have a limited window of 20 minutes to submit! The mixture over-catalyzes after that and looks chalky. And once applied, it won’t buff up if the coating’s dull and chalky! The color that gets wet is the color that dries.

Speaking of color, you’ll want to add the color pigment (if white isn’t for you) at this point in the process.

Should You Spray or Brush on the Gelcoat

It’s time to apply it after you’ve mixed your gelcoat batch and applied the requisite amount of hardener.

What’s the easiest way to get this done?

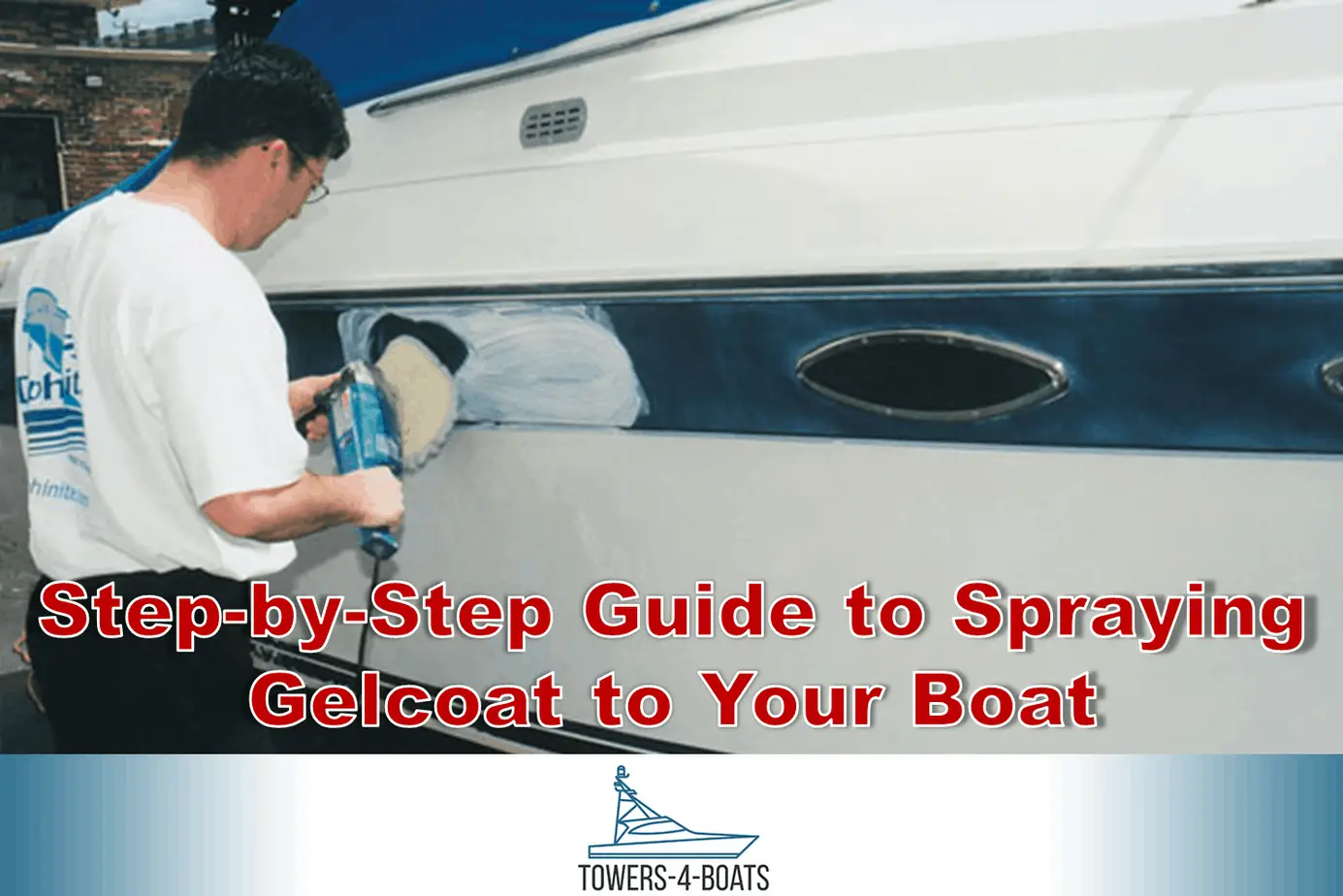

How to Brush Gelcoat onto Your Boat

If the craft or the region you are gel coating is smaller in size, so there is much less trouble with brushes. I agree there’s no substitute for ultimate smoothness for spraying gelcoat finish, but why do all that cost when a brush is going to do it? Accept that and pass on, the finish will be less professional-looking.

To achieve the same thickness as a spray gun, you can need to add two or three coats with the brush on the flipside. And if you’re planning to cover the entire hull of your boat and it’s a big enough job to warrant some investment in the result, choose a spray cartridge.

Applying Gelcoat with a Sprayer

You might spend anywhere from $65 to $1650 on a spray gun (Check Amazon), but I expect you’re getting a gun that’ll do the job just fine if you pay about $130.

Investing in an air compressor (Check Amazon) is also worth it, especially if the gun doesn’t have one built-in. Some do, like the Homeright Finish Max (Check Amazon), which makes life easier when spraying areas that are difficult to reach.

Now, stand about a foot apart to apply the gelcoat (0.30 meters). Function in sweeping motions (be careful not to stall when you hit the end) and make sure that during each application you overlap slightly, so no bits are lost.

Leave the gelcoat to set for the next four hours after you’ve finished the work. Leave it overnight for the best performance.

Which Gelcoat Brands are the Best

Sea Hawk Gelcoat (Check Amazon): a premium marine gelcoat engineered to protect against the sanding of water and the rigors of the sea.

Shulman White Gelcoat Kit (Check Amazon): This high-grade gelcoat comes with the comfort of the hardener.

This non-sagging, high viscosity formula is easy to apply and has excellent coverage: Complete Boat Gelcoat Neutral without Wax (check price on Amazon):

Ongoing Maintenance

The last thing you want is to ruin the end because you missed the aftercare after all this hard work and attention to detail.

Always store your boat in a dust-free area overnight. Letting the resin set overnight gives the gelcoat a tougher surface and a longer life. And, when recovering, stop storing the boat in direct sunlight.

When the gel coat is placed, check the surface for any blemishes. Another coat may need to be added. Check carefully for bubbles and blisters and treat them immediately; they are the coating’s weakest points and can cause your fiberglass hull to absorb water.

And that’s not what you want, especially when a well-applied Gelcoat can last 10 years or longer!

The Takeaway

For the longevity of your ships, the gel coat is important. The very thing that protects you is shielded by it: the hull!

So, for a simple life, why would you risk everything? Sure, the gel coat is not the simplest of tasks to spread and spray, and yes, it’s pretty messy. But if you’re done right, it gives you another 10 years of sailing and understanding that your hull doesn’t just look fine, it doesn’t help you weather the rough seas.